Tuned (semi-variable) capacitors allow the capacitance to vary within small limits. They are used for precise fixed adjustment of the capacitance of oscillatory circuits in high-frequency circuits to change the magnitude of the coupling between circuits, as well as for adjusting the capacitance during the repair and adjustment of radio receivers. Typically these capacitors are connected in parallel with the main capacitors of larger capacity.

Trimmed capacitors (Fig. 20) consist of two ceramic elements: a fixed base - the stator and a movable disk - the rotor or plunger (in KPK-T). The thinnest silver plates in the form of sectors are applied to the rotor and stator using the burning method. The dielectric between the stator and rotor plates can be air, ceramics or mica. The terminals from the plates are made in the form of contact petals, intended for soldering the wiring of the circuit.

The rotor is rigidly mounted on an axis, which can be rotated using a screwdriver. When the rotor rotates, the relative position (overlap) of the stator and rotor plates changes, and, consequently, the capacitance of the capacitor. When a sector or drop of solder on the rotor is located opposite the terminal on the stator, the capacitance will be maximum, and when the rotor is rotated 180° relative to the indicated position, it will be minimum. The design of tubular trimmed capacitors is somewhat different from that described above. In them, a change in capacity is achieved by moving a plunger in a ceramic tube.

For chassis mounting, ceramic trimmed capacitors have holes in the ceramic base for screws or other fasteners.

The industry produces several types of tuning capacitors. KPK capacitors (ceramic tuning capacitors) are manufactured for a rated DC voltage of 500 V. Depending on the design, KPK capacitors are produced in several types: KPK-1 - with a rotor with a diameter of about 18 mm, KPK-2, KPK- 3 and KPK-5 - with a rotor with a diameter of about 33 mm. In addition, KPK-5 has an adjusting screw, which is directly connected to the rotor lining.

The negative TKE of a KPK type capacitor allows for temperature compensation in oscillatory circuits, since the inductors in the circuits have a positive temperature coefficient of inductance.

The marking of PDA capacitors indicates the type and type of capacitor and the value of the minimum and maximum capacitance (pF). For example: KPK-3-125/250.

KPK-T (tube ceramic tuning) capacitors are designed to operate in circuits with a rated DC voltage of 500 V. The ceramic dielectric allows them to be used in radios and other radio devices.

KPK-M capacitors (small-sized ceramic tuning capacitors) are designed to operate in the temperature range from -20 to +80°C at a rated DC voltage of 350 V. They are available in two versions: N - for wall-mounted installation; P - for printed circuit installation.

Semi-variable capacitors of the KPK-MP types with a capacity of 4...15 pF, KT-4-2 with a capacity of 5...20 pF are mainly used as tuning capacitors in high-frequency and local oscillator circuits in transistor receivers.

KPV capacitors (tuning capacitors with an air dielectric) are produced in five modifications with a minimum capacitance range of 4...50 pF and a maximum range of 8...140 pF, for a rated DC voltage of 300 V. Small-sized capacitors (KPVM type) are produced for a rated voltage 350... 650 V. By design, capacitors of the K.PVM type are direct-capacitance with a rotation angle of 180° and have 14 modifications in capacitance with a minimum value of 1.8...6.5 pF and a maximum value of 3.8...24 pF . Capacitors of type 2KPVM have a rotation angle of 90° and are designed for adjusting high-frequency circuits in the VHF and DCV ranges. In terms of capacitance, these capacitors have 12 modifications with a minimum capacitance of 1...1.3 pF and a maximum of 1.5...2.8 pF. Capacitors of the ZKPVM type are differential and are available in 14 modifications with a minimum capacitance of 2.5...6.5 pF and a maximum of 3...24 nF. Miniature ceramic semi-variable capacitors K.T4-2 and KT4-1T are designed for printed circuit radio devices,

To fine-tune circuits during the production and operation of electronic devices, tuning capacitors are used, with the help of which the scatter of circuit parameters is compensated. Unlike variable capacitors, tuning capacitors have a relatively small change in capacitance. After adjusting the REA, the moving part of the capacitor is fixed with simple locking devices or wax.

Trimmer capacitors are characterized by the same parameters as variables. However, they are subject to a number of specific requirements: stability of the container in a fixed position, high reliability of such fixation, smooth installation of the container.

Trimmer capacitors are available with air and solid dielectric. The design of air tuning capacitors with a rotating rotor is similar to that of variable capacitors, but the rotor is shortened and a slot (slot) is made at its end for rotation of the rotor (see Fig. 2.5).

The most widely used are disk ceramic tuning capacitors with a rotating rotor in the form of a disk (Fig. 2.6). Such capacitors consist of a solid ceramic stator and a disk-shaped rotor. A silver metal film in the form of a semicircle is applied to the surface of the stator and rotor. The dielectric is titanium ceramic with high dielectric constant and an air gap between the rotor and stator. The disadvantage of such capacitors is the change in capacitance with pressure on the rotor and the large spread of TKE. However, such tuning capacitors are small in size and low in cost.

The designation system for trimmer capacitors corresponds to that adopted for permanent capacitors, which is described in section 2.2.2, and consists of two letters CT(tuning capacitor), a number indicating the type of dielectric according to Table 2.4, and a number indicating the serial number of the development of the capacitor.

For example: KT4-21 2.0/10– trimming capacitor with ceramic dielectric, development serial number 21, minimum capacitance 2 pF, maximum capacitance 10 pF.

Before the current designation system, tuning capacitors were designated by a set of two to four letters, which reflected the type of dielectric and its design features.

For example: KPK-MT– small-sized heat-resistant ceramic tuning capacitor.

Variconds are capacitors whose capacitance changes dramatically depending on the applied voltage. This effect is achieved by using ferroelectric ceramics based on barium and strontium titanates as a dielectric. Since in ferroelectrics the dependence of the electric displacement vector on the applied field strength is nonlinear, this causes the dielectric constant to depend on the applied electric field (Fig. 2.7).

The main parameters of varicondes are the following:

Nominal capacity – this is a capacitance that is measured at an alternating current voltage of 5 V with a frequency of 50 Hz or at an alternating current voltage of 1.5 ... 2 V with a frequency of 1000 Hz. The conditions for measuring the nominal capacitance depend on the type of variconde. The nominal capacity is indicated on the variconde body. Intermediate values of the nominal capacitance of varistors correspond to rows E6 and E12.

Nonlinearity coefficient for AC voltage – it shows how many times the capacitance of the varicond increases when the alternating current voltage with a frequency of 50 Hz changes from 5 V to the voltage value at which the maximum capacitance value is reached.

Constant voltage control coefficient – This is a coefficient that shows how many times the varicond capacity decreases when the DC voltage changes from 0 to 200 V.

TO  The design of variconds corresponds to the design of permanent capacitors with a volumetric dielectric - disk or rod (Fig. 2.8).

The design of variconds corresponds to the design of permanent capacitors with a volumetric dielectric - disk or rod (Fig. 2.8).

Variconds are widely used for rapid adjustment of resonant circuits using electrical control.

The varicond designation system corresponds to that adopted for permanent capacitors, which is described in section 2.2.2, and consists of two letters KN(nonlinear capacitor), a number indicating the type of dielectric according to Table 2.4, and a number indicating the serial number of varicond development.

For example: KN1-5 4.7 pF– nonlinear varicond capacitor, development serial number 5, nominal capacitance 4.7 pF.

Before the current notation system, varicondas were designated by a set of letters VC and numbers that reflected the design features of the variconde.

For example: VK2-B– varicond design type 2, non-insulated.

They are polar and non-polar. Their differences are that some are used in DC voltage circuits, while others are used in AC circuits. It is possible to use permanent capacitors in alternating voltage circuits when they are connected in series with like poles, but they do not show the best parameters.

Non-polar, just like resistors, can be fixed, variable or adjustable.

Trimmers capacitors are used to tune resonant circuits in transmitting and receiving equipment.

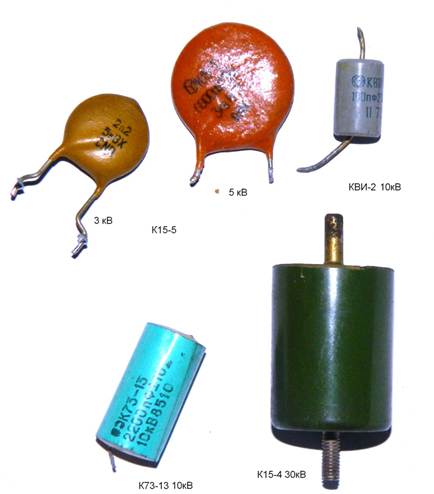

Rice. 1. PDA capacitors

PDA type. They consist of silver-plated plates and a ceramic insulator. They have a capacity of several tens of picofarads. It can be found in any receivers, radios and television modulators. Trimmer capacitors are also designated by the letters KT. Then follows a number indicating the type of dielectric:

1 - vacuum; 2 - air; 3 - gas-filled; 4 - solid dielectric; 5 - liquid dielectric. For example, the designation KP2 means a variable capacitor with an air dielectric, and the designation KT4 means a tuning capacitor with a solid dielectric.

Rice. 2 Modern trimming chip capacitors

To tune radio receivers to the desired frequency, use variable capacitors(KPE)

Rice. 3 Capacitors KPE

They can only be found in transmitting and receiving equipment

1- KPE with an air dielectric, can be found in any radio receiver of the 60s-80s.

2 - variable capacitor for VHF units with vernier

3 - variable capacitor, used in receiving technology of the 90s to this day, can be found in any music center, tape recorder, cassette player with a receiver. Mostly made in China.

There are a great many types of permanent capacitors; within the framework of this article it is impossible to describe all their diversity; I will only describe those that are most often found in household equipment.

Rice. 4 KSO capacitor

KSO capacitors - Pressed mica capacitor. Dielectric - mica, plates - aluminum coating. Filled in a brown compound housing. They are found in equipment from the 30s to the 70s, the capacity does not exceed several tens of nanofarads, and is indicated on the housing in picofarads, nanofarads and microfarads. Thanks to the use of mica as a dielectric, these capacitors are capable of operating at high frequencies, since they have low losses and have a high leakage resistance of about 10^10 Ohms.

Rice. 5 Capacitors KTK

KTK capacitors - Tubular ceramic capacitor. A ceramic tube and silver plating are used as a dielectric. Widely used in oscillatory circuits of lamp equipment from the 40s to the early eighties. The color of the capacitor indicates TKE (temperature coefficient of change of capacitance). Next to the container, as a rule, the TKE group is written, which has an alphabetic or numerical designation (Table 1.) As can be seen from the table, the most heat-stable ones are blue and gray. In general, this type is very good for HF equipment.

Table 1. TKE marking of ceramic capacitors

When setting up receivers, you often have to select capacitors for the local dyne and input circuits. If the receiver uses KTK capacitors, then selecting the capacitance of the capacitors in these circuits can be simplified. To do this, several turns of PEL 0.3 wire are wound tightly onto the capacitor body next to the terminal and one of the ends of this spiral is soldered to the terminal of the capacitors. By spreading and shifting the turns of the spiral, you can adjust the capacitance of the capacitor within small limits. It may happen that by connecting the end of the spiral to one of the terminals of the capacitor, it is not possible to achieve a change in capacitance. In this case, the spiral should be soldered to another terminal.

Rice. 6 Ceramic capacitors. Soviet ones at the top, imported ones at the bottom.

Ceramic capacitors are usually called “red flag” capacitors, sometimes called “clay” capacitors. These capacitors are widely used in high frequency circuits. Typically, these capacitors are not quoted and are rarely used by hobbyists, since capacitors of the same type can be made of different ceramics and have different characteristics. Ceramic capacitors gain in size but lose in thermal stability and linearity. Capacity and TKE are indicated on the body (Table 2.)

table 2

Just look at the permissible change in capacitance for capacitors with TKE N90, the capacitance can change almost twice! For many purposes this is not acceptable, but still you should not reject this type; with a small temperature difference and not strict requirements, they can be used. By using parallel connection of capacitors with different TKE signs, it is possible to obtain a fairly high stability of the resulting capacitance. You can find them in any equipment; the Chinese are especially fond of them in their crafts.

They have a capacity designation on the body in picofarads or nanofarads; imported ones are marked with a numerical code. The first two digits indicate the capacitance value in picofarads (pF), the last two digits indicate the number of zeros. When the capacitor has a capacitance of less than 10 pF, the last digit may be "9". For capacitances less than 1.0 pF, the first digit is “0”. The letter R is used as a decimal point. For example, code 010 is 1.0 pF, code 0R5 is 0.5 pF. Several examples are collected in the table:

Alphanumeric marking:

22p-22 picofarads

2n2- 2.2 nanofarads

n10 - 100 picofarads

I would like to especially note ceramic capacitors of the KM type, they are used in industrial equipment and military devices, they have high stability, they are very difficult to find because they contain rare earth metals, and if you find a board where this type of capacitor is used, then in 70% of cases they were cut out before you).

In the last decade, radio components for surface mounting have very often begun to be used; here are the main standard sizes of housings for ceramic chip capacitors

MBM capacitors are a metal-paper capacitor (Fig. 6), usually used in tube sound amplification equipment. Now highly prized by some audiophiles. This type also includes military-grade K42U-2 capacitors, but they can sometimes be found in household equipment.

Rice. 7 Capacitor MBM and K42U-2

It should be noted separately that such types of capacitors as MBGO and MBGCh (Fig. 8), are often used by amateurs as starting capacitors to start electric motors. As an example, my engine reserve is 7 kW (Fig. 9.). Designed for high voltage from 160 to 1000V, which gives them many different applications in everyday life and industry. It should be remembered that for use in a home network, you need to take capacitors with an operating voltage of at least 350V. You can find such capacitors in old household washing machines, various devices with electric motors and in industrial installations. They are often used as filters for acoustic systems, having good parameters for this.

Rice. 8. MBGO, MBGCH

Rice. 9

In addition to the designation indicating design features (KSO - compressed mica capacitor, KTK - ceramic tubular capacitor, etc.), there is a designation system for constant-capacity capacitors, consisting of a number of elements: in the first place is the letter K, in the second place is a two-digit number, the first digit of which characterizes the type of dielectric, and the second - the features of the dielectric or operation, then the serial number of the development is put through a hyphen.

For example, the designation K73-17 means a polyethylene-terephthalate film capacitor with a development serial number of 17.

Rice. 10. Different types of capacitors

Rice. 11. Capacitor type K73-15

Main types of capacitors, imported analogues in parentheses.

K10 - Ceramic, low voltage (Upa6<1600B)

K50 - Electrolytic, foil, Aluminum

K15 - Ceramic, high voltage (Upa6>1600V)

K51 - Electrolytic, foil, tantalum, niobium, etc.

K20 - Quartz

K52 - Electrolytic, volumetric porous

K21 -Glass

K53 - Oxide semiconductor

K22 - Glass-ceramic

K54 - Oxide-metallic

K23 - Glass enamel

K60- With air dielectric

K31-Mica low power (Mica)

K61 - Vacuum

K32 - Mica high power

K71 - Film polystyrene (KS or FKS)

K40 - Paper low-voltage (Irab<2 kB) с фольговыми обкладками

K72 -Film fluoroplastic (TFT)

K73 - Film polyethylene tereph-talate (KT, TFM, TFF or FKT)

K41 - Paper high-voltage (irab>2 kB) with foil coverings

K75 -Film combined

K76 – Lacquer film (MKL)

K42 - Paper with metallized covers (MP)

K77 - Film, Polycarbonate (KC, MKC or FKC)

K78 – Film polypropylene (KP, MKP or FKP)

Capacitors with a film dielectric are popularly called mica; the various dielectrics used give good TKE indicators. As plates in film capacitors, either aluminum foil or thin layers of aluminum or zinc deposited on a dielectric film are used. They have fairly stable parameters and are used for any purpose (not for all types). They are found everywhere in household equipment. The housing of such capacitors can be either metal or plastic and have a cylindrical or rectangular shape (Fig. 10.) Imported mica capacitors (Fig. 12)

Rice. 12. Imported mica capacitors

On capacitors, the nominal deviation from the capacitance is indicated, which can be shown as a percentage or have a letter code. Basically, in household equipment, capacitors with tolerances H, M, J, K are widely used. The letter indicating the tolerance is indicated after the value of the nominal capacitance of the capacitor, like 22nK, 220nM, 470nJ.

Table for deciphering the conditional letter code of the permissible deviation of capacitor capacitance. Tolerance in %

|

Letter designation |

||

The value of the permissible operating voltage of the capacitor is important; it is indicated after the rated capacity and tolerance. It is designated in volts with the letter B (old marking) and V (new marking). For example, like this: 250V, 400V, 1600V, 200V. In some cases, the V is omitted.

Sometimes Latin letter coding is used. To decipher, you should use the letter coding table for the operating voltage of capacitors.

|

Rated voltage, V |

Designation letter |

Fans of Nikola Tesla have a frequent need for high-voltage capacitors, here are some that can be found, mainly in televisions in horizontal scanning units.

Rice. 13. High voltage capacitors

Polar capacitors include all electrolytic ones, which are:

Aluminum electrolytic capacitors have high capacity, low cost and availability. Such capacitors are widely used in radio instrument making, but have a significant drawback. Over time, the electrolyte inside the capacitor dries out and they lose capacity. Along with the capacitance, the equivalent series resistance increases and such capacitors no longer cope with the assigned tasks. This usually causes malfunctions in many household appliances. Using used capacitors is not advisable, but still, if you want to use them, you need to carefully measure the capacitance and esr, so that you don’t have to look for the reason for the device’s inoperability. I don’t see any point in listing the types of aluminum capacitors, since there are no special differences in them, except for geometric parameters. Capacitors can be radial (with leads from one end of the cylinder) and axial (with leads from opposite ends), there are capacitors with one lead, the second one is a housing with a threaded tip (it is also a fastener), such capacitors can be found in old tube radio-television equipment. It is also worth noting that on computer motherboards and in switching power supplies there are often capacitors with low equivalent resistance, the so-called LOW ESR, so they have improved parameters and are replaced only with similar ones, otherwise there will be an explosion when first turned on.

Rice. 14. Electrolytic capacitors. Bottom - for surface mounting.

Tantalum capacitors are better than aluminum capacitors due to the use of more expensive technology. They use a dry electrolyte, so they are not prone to “drying out” of aluminum capacitors. In addition, tantalum capacitors have lower active resistance at high frequencies (100 kHz), which is important when used in switching power supplies. The disadvantage of tantalum capacitors is the relatively large decrease in capacitance with increasing frequency and increased sensitivity to polarity reversal and overloads. Unfortunately, this type of capacitor is characterized by low capacitance values (usually no more than 100 µF). High sensitivity to voltage forces developers to increase the voltage margin by two or more times.

Rice. 14. Tantalum capacitors. The first three are domestic, the penultimate one is imported, the last one is imported for surface mounting.

Main dimensions of tantalum chip capacitors:

One of the types of capacitors (in fact, these are semiconductors and have little in common with ordinary capacitors, but it still makes sense to mention them) include varicaps. This is a special type of diode capacitor that changes its capacitance depending on the applied voltage. They are used as elements with electrically controlled capacitance in circuits for tuning the frequency of an oscillatory circuit, dividing and multiplying frequencies, frequency modulation, controlled phase shifters, etc.

Rice. 15 Varicaps kv106b, kv102

Also very interesting are “supercapacitors” or ionistors. Although small in size, they have enormous capacity and are often used to power memory chips, and sometimes they replace electrochemical batteries. Ionistors can also work in a buffer with batteries in order to protect them from sudden surges in load current: at low load current, the battery recharges the supercapacitor, and if the current increases sharply, the ionistor will release the stored energy, thereby reducing the load on the battery. With this use case, it is placed either directly next to the battery or inside its housing. They can be found in laptops as a battery for CMOS.

The disadvantages include:

Energy density is lower than that of batteries (5-12 Wh/kg at 200 Wh/kg for lithium-ion batteries).

The voltage depends on the state of charge.

Possibility of internal contacts burning out during a short circuit.

High internal resistance compared to traditional capacitors (10...100 Ohm for a 1 F × 5.5 V ionistor).

Significantly greater self-discharge compared to batteries: about 1 µA for a 2 F × 2.5 V ionistor.

Rice. 16. Ionistors

§ 3. Tuned capacitors

Ceramic tuned capacitors are widely used in oscillatory circuits for fine tuning during the process of setting up radio equipment

TableII.;"

Basic data of ceramic ppd capacitors

|

Capacity change limits, pf |

TKE. %/deg |

Tmngens of dielectric loss angle |

Rlmsry building.1. mm |

Weight. G(no more) |

|

|

2-7 * : 4-15; 6-25: 8-30; 6-60; 25-150; 75-200 |

|||||

|

1^5-250; 200-325; |

|||||

|

275 - 375; 350- 450; |

|||||

|

4_|5: 5-20; 6-25; 8-30 |

|||||

|

2-7; 4-15; 6-25; 8-30 |

|||||

|

1_Yu; 2-15: 2-20; 2-25 |

* TKE is not standardized.

Four types of ceramic tuning capacitors are available: 1) Efficiency - ceramic disk tuning capacitors; ?) KPK - ceramic trimming capacitors;

3) KPKMT - small-sized ceramic tuning capacitors, tropical-resistant;

4) KPKT - ceramic tubular tuning capacitors. The appearance of the tuning capacitors is shown in Fig. 11.8, and the main data are given in table. 11.19.

Plate tuning capacitors are miniature tuning capacitors like I wash bone capacitors of variable capacitance with an air dielectric (Fig. A.8). They are characterized by high quality indicators, but are complex in design and expensive.

§ 4. Capacitorsvariablecontainers

The basic parameters of variable capacitors are the same as those of constant capacitors (see § 1). One of the main characteristics of variable capacitors is the law of change in speed depending on the angle of rotation of the movable plates (rstor), which determines the law of change in frequency when tuning the circuit. They produce direct-frequency, logarithmic, primary-capacitive and direct-wave variable capacitors. They are manufactured with air and solid dielectric. Capacitors with an air dielectric are characterized by higher performance, in particular greater accuracy of capacitance setting and stability. Capacitors with a solid dielectric are small in size and therefore used in small-sized equipment.

In table 11.20 shows the basic data of typical small-sized variable capacitors with a solid dielectric. These capacitors are intended for radio receivers operating on transistors.

Table 11.20

Basic data of typical small-sized capacitorsvariable capacity

|

Where installed |

Law of Capacity Change |

Capacity change limits. pf |

Dielectric loss tangent |

Case dimensions, mm |

The length of the protruding part with the axis, mm |

Weight, g (no more) |

|

Direct capacitance |

||||||

|

Straight wave |

||||||

Note. The capacitors are made in the form of blocks of two sections.

Ceramic tuning capacitors TKPA KPK can be used as tuning capacitors for small-sized radio receivers. To increase their service life, a chromium or nickel film with a thickness of 1.0-1.5 is electroplated onto the silver coating of the stator. mk. You can also solder a plate of brass or copper foil with a thickness of 0.05-0.1 mm. The following method is recommended: cutting the workpiece to the shape of the silver coating of the stator

In everyday life, this is the name for products made by firing a mass, mainly clay. In technology, ceramic means materials with a similar structure, although they do not contain clay at all, or it is present in small quantities. These include capacitor ceramics, used as the dielectric of capacitors.

Ceramic capacitors

Such products are characterized by high electrical performance, small size and low cost. Ceramic capacitors are widely used in radio circuits. They come with constant capacity and tuning ones.

with constant capacity

Thermally stable ceramic capacitors are used in high-stability generator and local oscillator circuits. To restore the temperature, thermal compensating elements are used. A special group consists of ferroelectric ceramic capacitors, in which ferroelectric ceramics are used as a dielectric - a material with very high (up to several thousand) temperatures in a certain temperature range. The mentioned products differ from high-frequency ceramics in having a larger capacity with the same dimensions.

A ceramic tubular capacitor (KT-1, KT-2) is a thin-walled tube, the outer and inner surfaces of which are coated with a layer of silver.

Ceramic disk capacitor (KD1, KD2) and disk ferro-ceramic models (KDS1, KDS2, KDS3) are a round ceramic plate with a lining in the form of thin layers of silver.

Ceramic barrel element molded with plastic (KOB1, KOB2, KOB3) is a ceramic cylinder, on the base of which linings are also applied.

Color scheme and its meaning

The different colors in which KT, KDS, KD, etc. products are painted indicate the stability of their capacity when temperature changes. and gray paint is used if it reacts slightly to changes in temperature. Such elements are called thermostable. Red and green colors mean that as the temperature rises, the capacitance of the products will noticeably decrease - these are temperature-compensating capacitors. indicates that if the temperature changes over a wide range, the capacity of the product will change quite significantly (however, the capacity remains stable).

Types of ceramic trimmer capacitors

These products are designed to adjust (adjust) the parameters of oscillatory circuits; they are also called semi-variables. Let's briefly look at each of them.

A ceramic trimmer capacitor (CTC) consists of a ceramic base (stator) and a ceramic movable disk (rotor). The disk on the axis is attached to the stator and can be rotated using a screwdriver. Silver plates, shaped like sectors, are applied to the planes of both components. The rotor material is dielectric. During rotation, the relative position of the plates changes, and, accordingly, the capacitance between them.

Ceramic tubular tuning capacitor (CPCT) - the name itself suggests that the product in question has the form of a tube. A thin silver fixed lining is also applied to its inner surface - a metal rod with a screw thread. When rotated (achieved using a screwdriver), the capacity changes due to the insertion or removal of the rod from the tube.

Capacity of ceramic capacitors

Just 10-20 years ago, due to difficulties associated with the production of the mentioned capacitors, the products were classified as low-capacity devices. More recently, a 1 µF ceramic capacitor would not have surprised anyone, but a 10 µF element was perceived as exotic.

But today, the development of technology has allowed some manufacturers of radio components to declare that the capacitance limit in such capacitors has reached 100 μF, but, as they assure, this is not the limit.