It doesn’t matter whether you decorated the Christmas tree or decorated the window with a garland. There comes that crucial moment when, after applying power, it does not light up. And this is understandable, because during the “rest” period its various modules, such as the power supply, LED lamps or the wiring itself, may fail. You can correct the situation by going to the store and buying a new Christmas tree garland, but if you spend a little time, you can repair it yourself.

LEDs have parameters that characterize their operating environment - these are operating voltage and operating current, which vary depending on the type of LED. The main electrical parameter is current strength. And if you decide to ring the LED yourself, you need to take these parameters into account. But if the operating current and voltage are unknown, use two proven dialing methods.

Namely:

Before checking the LED for operability, it is necessary to disconnect it from the contacts or unsolder it. It is known that an LED, at its core, is an ordinary semiconductor (passing electric current in one direction) and has two contacts (anode and cathode) in the form of elongated legs made of copper (or iron). With their help the dialing will be made.

Set the multimeter to dialing mode. In this mode, the current passing through the LED will be approximately 1 mA. We touch the probes of the LED contact tester and observe the readings on the multimeter screen. You can also shade the room to monitor the glow of the diode.

The dialing is carried out in two positions, so you will find out the location of the cathode and anode of the working LED. If the LED fails, it does not light up, and the constant indicator on the tester will be one.

If you don’t have a multimeter and you need to make a test, you can use a regular 9-volt battery. Since connecting the diode directly to the battery will lead to its failure, we use a finger soaked in water as a lowering resistor (resistance). We touch the plus of the battery with the anode, put our finger on the minus and touch it with the cathode. If the polarity is not observed, there is nothing critical about it, we turn the diode over and check it.

Before repairing the garland, it is necessary to diagnose the breakdown visually or using instruments.

Types of faults:

If there is no glow of one or more colors, the first thing you need to do is disassemble the control unit and make sure that all the wires are securely soldered to the microcircuit. Solder the unsoldered wires back into place. If the wires are in order and the lamps (LEDs) do not light up, then you need to look (by checking) for a burnt-out light source. The most convenient way to do this is to pierce the wire on both sides of the lamp (LED) with needles so that they touch the conductive core and, touching both needles with probes, ring each light source.

To troubleshoot the common wire, we also check whether it is soldered to the board in the control unit. If the soldering is in order, visually or by testing it is necessary to find the break point of the common wire.

Before starting repair work, make sure that the product is disconnected from the electrical network.

Failed lamps must be replaced. If it is not possible to replace the light bulb (there are no similar lamps available), we remove the socket from the electrical circuit, and the wires at the break point must be connected directly. We twist, solder and insulate. Thus forming an unbreakable chain.

The control unit must also be replaced, followed by soldering all the wires to the microcircuit according to the instructions. If the fault is related to the network cable, you need to check its integrity or the quality of the contact in the control unit. The best option would be to replace the network cable, especially if you are using an inexpensive Chinese garland. In duralight garlands, visually and using a tester you need to find the damaged area, cut it off and connect the remaining parts with connectors.

A huge difference and advantage of Soviet garlands from those currently produced was their reliability. Like any device, the garlands of those times failed and had to be repaired. But with the help of modern devices and tools it is easy to identify the malfunction, repair it and make the garland work.

Depending on the breakdown, the work will require:

After you have taken the garland out of the box, tried to connect it to the network, and a check has shown that it does not work (the lights do not light), you can begin the repair. Since in a garland the connection diagram of the circuit elements is sequential (if one lamp fails, the entire garland stops working), first of all we check the light bulbs for integrity.

If the garland uses colored light bulbs, and you only have a regular one, you can paint it with tsapon lacquer of a suitable color.

If the lamps are intact, but the garland refuses to work, check how they are screwed into the sockets. If necessary, tighten the light bulb.

If all these manipulations do not help, you can move on to the third method. Using an indicator screwdriver (these are usually used to detect hidden wiring), we look for the place where the wire contact is broken. A broken contact can occur either in the wire itself or in the socket (the contact has become unsoldered). We plug the garland into the network and, touching the wire insulation, find the damaged area. If necessary, solder the contact in the socket or, removing the socket, connect the wires directly.

Everyone has long known about the quality of cheap Chinese garlands. Unreliable connections, thin wires and much more, which leads to frequent breakdowns. Also, elements of the control unit board often become unusable.

Control unit malfunctions:

The failure of an individual circuit element directly affects the operation of the garland. For example, a faulty capacitor or one of the resistances leads to its random blinking. A burnt diode or the entire diode bridge to which a voltage of 220 V is suitable, like the microcircuit, will completely stop its operation. When a thyristor fails, one of the circuit channels stops working. All of them are subject to replacement. But if you don’t have an electrical engineering education or don’t want to bother with a soldering iron, you can resort to a very simple scheme to turn any ordinary garland into a “flashing light.” To do this, you need to connect the garland directly with the plug, and build a regular starter from fluorescent lamps into one of the cable wires.

This scheme is applicable only for garlands equipped with lamps; the LEDs will glow dimly and without flickering.

If you want to control the flicker frequency, a 0.5 to 2 µF capacitor is added to the starter circuit.

If your garland is out of order, you don’t need to ask yourself why? The right solution would be to understand what the reason is and how to repair it. After all, some breakdowns are quite easy to fix on your own, and with a little effort and spending some time, you can cope with more complex faults.

The New Year holidays are approaching and on this occasion I want to do something bright and festive! I decided to make a New Year's garland. What could be brighter and more festive than a New Year's garland? :). I decided to make not a simple garland, but a sophisticated one! 12 channels plus control from an IR remote control. In order not to make a garland from scratch, it was decided to use donors internal organs For spare parts, use ready-made Chinese garlands. This makes sense for the following reasons:

— the cost of the garlands, let’s be honest, the cost is a pittance. Try to buy wires, LEDs, spare parts for the same money... And if you don’t take an LED garland as your goal, then light bulb garlands are now sold for almost nothing;

— an important factor is ready-made LED lines soldered together. Soldering yourself, heat shrinking, making mistakes and redoing 12 lines is quite a tedious job;

- yet, I don’t know about you, but I have a certain number of non-working garlands lying around (they are often brought to me to repair them - and they end up) you can not spend money on new ones at all, but collect them from what you have.

To get started, watch the video:

ATTENTION!

dangerous voltage 220V!

LIFE THREATENING!

THAT'S WHY:

If you realize the danger assembling such a garland and undertake to comply with safety rules when working with dangerous voltage, you can read further about how to assemble a super garland.

1 Garlands patients.

As sacrifices, 3 new LED garlands were purchased - they are beauties :)

Cost $3 per piece (100 LEDs). But if the Chinese don’t save, they will cheat on themselves! In fact, the garlands contained 3 channels. That is, the controller itself is four-channel, but there are three thyristors and three LED lines. In order to disguise such disgrace, the Chinese mix LEDs of two colors in one line. In short, I had to buy another one :(. But this is not the limit of savings, there are often two channels at all! Be careful - open the box and see how much the thyristors cost.

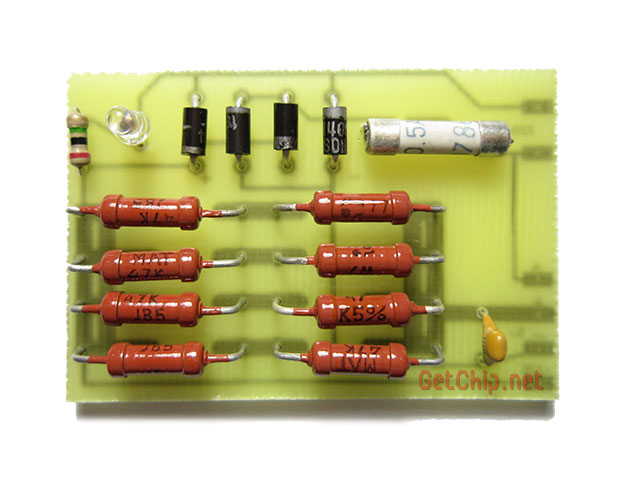

From the original controllers for the improved garland, resistors, rectifying diodes, thyristors, a button, and boxes will be used. You will need to buy a little more than a dozen resistors, a couple of capacitors, an ATtiny2313 microcontroller and other little things.

2 Scheme.

Here is a diagram of the original garland:

The diagram shows that dimming of LED channels is carried out by thyristors PCR406

Datasheet for thyristor PCR406

I don't see any point in changing them to something else. To generate the supply voltage of the original controller, a quenching resistor is used (the quenching resistor, together with the internal resistance of the controller, forms a voltage divider). The solution is controversial, but in this case it is justified by its low cost (the controller current is insignificant and the power allocated to the resistor is very small). Having weighed the pros and cons of such a decision, I decided to do something similar in my scheme. True, the ATtiny2313 current (within 8mA) is significantly higher than the original controller, but still allows the use of quenching resistors.

Diagram of the new garland controller:

6 Assembling the power supply board.

Before assembling the power supply board, you need to make certain measurements to calculate the value of the quenching resistors. To do this, we connect the soldered controller board with the firmware microcontroller to an EXTERNAL 5 volt source (+5v and -5v pads) and measure the current consumption. It is not necessary to connect the LED lines; they have virtually no effect on the current consumption. For a regular ATtiny2313 microcontroller without letter indices, the current consumption should be about 7 - 9 mA. For an ATtiny2313 microcontroller with indices (maybe A, P...) the current will be different.

Based on the received current consumption (Ipot), we calculate the resistance of the quenching resistors in the battery (we accept the larger one from the standard range):

R = 430 / Ipot

For example, my current consumption was 9 mA, which means R = 430 / 0.009 = 47777 Ohm (assuming 47 kOhm).

The stacking of quenching resistors is designed to distribute power dissipation and reduce heating. Resistors must have a power of at least 0.5 W (and preferably 1 W each).

The rectifying diodes and quenching resistor are migrated from the original circuit; the rest will have to be purchased. We place the finished board in the garland body.

We connect the power supply and controller boards (we take the wires and plug from the original garland). Don’t forget to secure the wires soldered to the boards with hot glue, since the wires used by the Chinese are, to put it mildly, crap and can fall off at any moment.

7 Formation of LED lines.

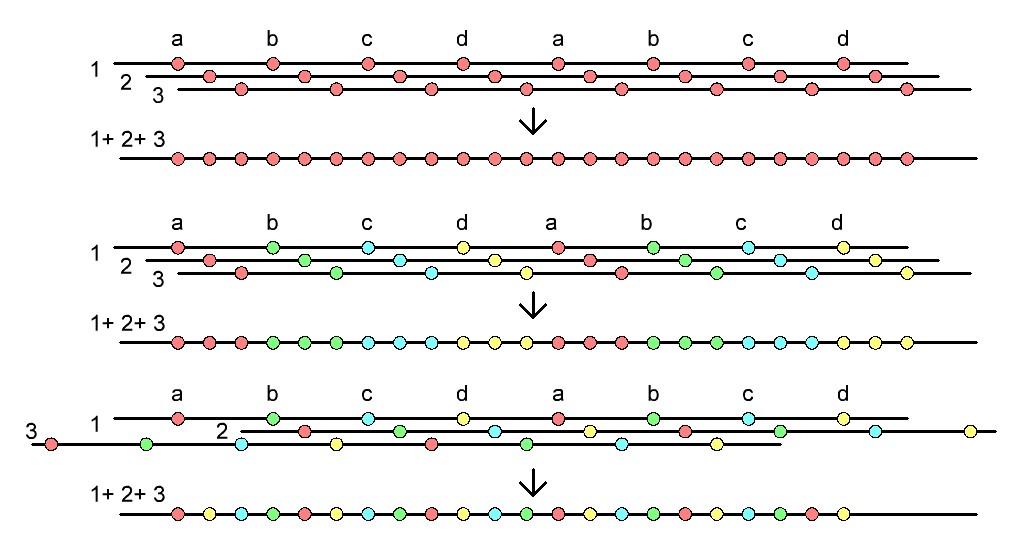

What you will have to tinker with is the formation of 12 channels of LED lines. It will be necessary to assemble a common harness with twelve lines (plus a common wire) from three bundles (and in the case of three channels in a garland, four bundles) of the original garlands. The garlands need not just be twisted together, but care must be taken to ensure that the LEDs of all twelve channels are arranged sequentially, one after the other. In addition, if the garland is multi-colored, you need to make sure that the colors are mixed as much as possible.

In general, for better visualization of effects, single-color garlands are better suited, but for creating a brighter image, multi-colored garlands, perhaps, win. Here you must decide either more expressive effects or a more colorful impression.

It takes a long time to explain in words - look at the pictures or think for yourself how to twist the bundles:

The harnesses are twisted - now we solder them to the controller so that the channel LEDs follow each other in series.

8 Description of the garland's operation.

When you plug the garland into the network, it immediately starts working with a random effect. During operation, the effects will randomly change each other. If you press the button, the effects will sequentially replace each other in turn:

1 Wave

2 Shooting Star

3 Sparks

4 Slow overflow

5 Running lights

6 Twinkling lights

7 Everything burns and goes out

8 Everything is on fire

0 All off

When you select an effect with the button, it lingers for a longer time, but later the effects will begin to replace each other again.

Operation from the remote control is similar to the operation of the button on the controller (press the button on the remote control - the effects change sequentially). To study the button of any IR remote control, you need to hold down the button on the controller until the garland goes out (about 3 seconds), then you need to press the selected button on the remote control. The button code will be written into non-volatile memory and the garland will return to the effects. Since the code is stored in non-volatile memory, the garland will “remember” the remote control even after being disconnected from the network.

Finally, I think it’s worth reminding:

ATTENTION!

The garland circuit is not galvanically isolated from the network dangerous voltage 220V!

Touching any conductive part of the garland connected to the network

LIFE THREATENING!

THAT'S WHY:

- if you are not well versed in electricity, do not repeat this design;

— any actions (soldering, measurements, etc.) with the circuit must be performed only after disconnecting from the network;

— programming the microcontroller must be done either separately from the board (for example, in a breadboard specially assembled for this purpose), or by powering the garland board from an external 5 volt source (for example, from batteries);

— the finished structure must be well insulated and inaccessible to small children and animals;

- Be careful when assembling the structure!

And here are examples, so to speak, live:

Send yours and I’ll add them here.

Christmas tree from AndreevKV. It turned out big! 🙂

Christmas tree from BOYka59. All my friends and especially the children are delighted with her)

And further!

Happy New Year!

Good mood and happy holidays to everyone!

Update 1 (2013)

I didn’t really plan to do anything with this garland, since I don’t have time for it this year, but at the request of readers I still decided on a small update!

Little changed.

Added 6 new effects:

— a wave of 2 LEDs running in different directions

— sequential filling and decreasing

— sequential filling and decreasing with a variable traveling wave

- random filling and deletion

- random filling and removal with variable traveling wave

- aggressive flicker

The operating time of the effect when forced switching (remote control or button) is almost doubled.

That's all. The circuit and fuses remain the same. It is necessary to re-upload the new firmware.

- 12-channel super garland (update 2013)

- Source of the supergarland update

Happy coming, now, 2014!!! 😉

Super garland options from blog readers

Sergey Cherniy (Bleck_S)

The garland is implemented on one board using SMD components

We are all familiar with Christmas tree garlands consisting of multi-colored light bulbs. However, recently products based on LEDs have become very popular.

How they are designed, what kind of connection diagram they have and what to do if the garland stops glowing will be discussed in detail in this article.

What does a Christmas tree garland consist of?

What is a garland of LEDs, is it worse or better than a regular one?

What is a garland of LEDs, is it worse or better than a regular one?

Externally, this is almost the same product as before - wires, light bulbs (LED), control unit.

The most important element is, of course, the control unit. A small plastic box on which various operating modes of the backlight are indicated.

They can be changed by simply pressing a button. The unit itself can be quite well protected with IP44 level of moisture and dust protection.

What's inside? To open it, use the sharp tip of a knife or a thin screwdriver to pry up the latches from below and remove the protective cover.

By the way, sometimes it is glued, and not just sitting on the latches.

First of all, inside you will see wires soldered to the board. The thicker wire is usually the network wire, supplying 220V voltage.

Soldered on the board:

The number of board elements depends primarily on the number of light channels of the garland. More expensive models may have a fuse.

The number of board elements depends primarily on the number of light channels of the garland. More expensive models may have a fuse.

LED garland diagram

The AC mains voltage is supplied to the power controller through resistors and a diode bridge, already rectified and smoothed through a capacitor.

In this case, this voltage is supplied through the button, which is open in the normal state. When you close it, the controller modes switch.

The controller in turn controls the thyristors. Their number depends on the number of backlight channels. And after the thyristors, the output power goes directly to the LEDs in the garland.

The more such outputs, the more varied the colors the product can have. If there are only two of them, this means that only two parts (or halves) of the garland will work in different modes - some bulbs will go out, others will light up, etc.

In fact, these two lines of diodes will be connected on two channels in series. They will connect to each other at the end point - the last LED.

If for some reason you are annoyed by the blinking of the garland and you want it to glow evenly with only one color, it is enough to short-circuit the cathode and anode of the thyristor on the back side of the board using soldering.

The more expensive the garland you have, the more outgoing channels and wiring will leave the control board.

At the same time, if you follow the traces of the board, one of the mains voltage outputs is always supplied directly to the final LED of the garland, bypassing all elements of the circuit.

Causes of malfunction

Situations with garland malfunctions are very diverse.

Situations with garland malfunctions are very diverse.

At the same time, remember that the most important element - the microcircuit on the board - “burns” very, very rarely.

In approximately 5-10% of all cases.

Bad soldering

If your backlight suddenly stops working, first of all always check the soldering of the supply and output wires. It is quite possible that the entire contact was held only by hot glue.

It’s worth moving the wiring and contacts as usual.

The most common problem with Chinese garlands is the use of very thin wires, which simply break off at the solder points on the board.

To prevent this from happening, all contacts after soldering must be covered with a thick layer of hot-melt adhesive.

And when stripping such veins, it is advised to use not a knife, but a lighter. Instead of whittling away the insulation with a blade, lightly heat and melt it with a lighter.

After that, simply remove the outer layer with your nails without damaging the veins themselves.

LED damage

If the wire contacts are OK and you are sinning on one of the diodes, how can you check if it is faulty? And most importantly, how to find it among the whole series of light bulbs?

First of all, unplug the garland from the outlet. Start with the last diode. The power wire comes to it directly from the control unit.

An outgoing conductor is soldered to the same leg. He goes to the next branch of the light channel. You also need to test the diode between its two power wires (input-output).

You will need a multimeter and its somewhat modernized probes.

Thin needles are tightly tied to the tips of the tester probes with a thread so that their points protrude a maximum of 5-8mm.

Wrap everything on top with a thick layer of electrical tape.

Since the LEDs are soldered, you won’t be able to simply pull them out of the light bulb like in regular garlands.

Therefore, you will have to pierce the insulation of the conductors to get to the copper conductors of the wiring. Switch the multimeter to diode testing mode.

And you begin to sequentially pierce the supply wires near each suspicious diode.

If you have a garland not 220V, but 12V or 24V, which is connected from this power supply:

then the working LED from the multimeter battery should light up.

If this is a 220V backlight, then check the multimeter readings.

On working elements they will be approximately the same, but the faulty one will show a break.

The method is of course barbaric and damages the insulation, but it works quite well. True, after such punctures, it is better not to use outdoor garlands outdoors.

Chaotic blinking

There is a situation when you turn on a garland and it starts blinking chaotically, sometimes brighter, sometimes dimmer. It sorts through the channels on its own.

There is a situation when you turn on a garland and it starts blinking chaotically, sometimes brighter, sometimes dimmer. It sorts through the channels on its own.

In general, one gets the impression that this is not some kind of factory effect, but as if the garland has “gone crazy”.

Most often the problem here is the electrolytic capacitor. It may swell and swell a little, and this will be clearly visible even to the naked eye.

Everything can be solved by replacing it. The denomination is indicated on the case, so you can easily purchase and select a similar one in radio parts stores.

If you replaced the capacitor, but it did not give any effect, where to look next? Most likely one of the resistors has burned out (broken). It is quite problematic to visually determine the breakdown. You will need a tester.

You take resistance measurements, having previously learned its nominal (normal) value from the markings. If it doesn't match, change it.

Part of the garland does not shine

When any of the channels on the garland does not work completely, there may be two reasons.

For example, a breakdown on one of the thyristors or diodes responsible for it.

To make sure of this for sure, simply unsolder the wiring of this channel on the board from its place and connect there the adjacent channel, which is known to be working.

And if at the same time another channel also stops working, then the problem is not in the garland itself, but in the components of its board - a thyristor or diode.

You check them with a multimeter, find the ones that match the parameters and change them.

The garland shines dimly

There are also not entirely obvious accidents, when the LEDs of a separate channel seem to be on, but rather dimly compared to the others.

What does it mean? The controller circuit is working fine. When you press the button, all modes are switched.

Testing the parameters of the diode bridge and resistance with a tester also does not reveal any problems. In this case, the only thing left to blame is the wires. They are already quite frail, and when such a multi-core wire breaks, its cross-section decreases even more.

As a result, the garland is simply not capable of starting the LEDs in the nominal brightness mode, since they simply do not have enough voltage. How to find this torn vein in a long garland?

To do this, you will have to walk along the entire line with your hands. Turn on the garland and start moving the wires near each LED until all the backlight lights up at full strength.

According to Murphy's Law, this may be the very last piece of garland, so be patient.

As soon as you find this area, pick up a soldering iron and disassemble the wires on the LED. Clean them with a lighter and solder everything again.

Then insulate the soldering area with heat shrink.

Unexpectedly, we discovered that the old garland that had been decorating the Christmas tree for many years no longer worked; there is no need to rush into buying a new one, because there is always a chance to repair it yourself. As a rule, such devices of Christmas tree lights are not such a complex design.

Therefore, if you carefully check the possible malfunctions, you won’t have to wonder how to fix a Chinese garland, the circuit of which is not difficult. So, if the contact wires in the garland come off, the light bulb burns out, or the mode switching is disrupted, then you should not throw it away. It is enough to use some effective tips.

The most time-consuming breakdown is considered to be the one when the color change in the Chinese garland is disrupted. Even if the solution to the problem is simple, restoring the device to its previous state will not be easy. A malfunction of the color mode indicates that the light bulbs in the corresponding section have burned out.

Before proceeding directly with the repair, it is recommended to disassemble the cover of the switch, which acts as a control unit, and check the reliability of the connections, especially the contacts soldered to the board.

If at first glance there are no signs of breakdown, then we can confidently say that the light bulb has burned out. Modern Chinese garlands are designed in such a way that all light bulbs of the same color are connected in series. And if one of them burns out, the light on the entire electrical branch will go out. To fix the breakdown, you need to use the LED Chinese garland circuit.

First, you should cut the garland into two equal parts and ring both sections. Then similar actions should be performed with the non-working side - cut into two halves and check again. Similar actions are carried out until it is possible to determine which of the bulbs is non-working. It should be noted that this method is recommended to be used only if the Chinese electric garland, the circuit of which allows you to speed up the process, is not disassembled.

The process of restoring the functionality of the garland can be accelerated. To do this, you need to take a tester and attach needles to its ends instead of probes. Then, using them, sequentially punch through each section of the chain so that the needle passes to the current core. It is necessary to determine where the section resistance differs significantly. In this way, you can identify a breakdown and repair it much faster, without putting in a lot of effort.

As a rule, old Soviet garlands for the New Year tree are much more convenient in this regard than a Chinese garland. Their circuits are almost similar, but the design is noticeably different. In Soviet ones, light bulbs are screwed into sockets. Therefore, it is possible to determine which of them is in working condition, without a soldering iron and an ohmmeter, only by elimination. This method involves taking a working light source and screwing it into the sockets one by one. Another way to use a tester is to measure the resistance of each individual lamp until you can find the burnt one.

Before trying to repair the garland, it is recommended to check the integrity of the common wire. For accuracy, you can refer to the Chinese garland diagram. On one side of the board you can see 5 soldered wires, 4 of which are intended for glowing colors, and one is common. And if the common wire breaks, it must be soldered.

If, after studying the diagram of the Chinese Christmas tree garland, it was not possible to find the cause of its breakdown, it is recommended to make sure that the problem is not in the LEDs. In this case, you should check the control unit and power cord. First, you need to make sure that the cord is intact, since there is a possibility that it was broken, or the contact connections at the connection to the microcircuit were broken. Then you need to try to check the reliability of the soldering of the contact connections to the board. Of course, in order not to suffer, you can buy a new garland, however, if you want to repair the device, then you should act.

So, the control unit can be replaced with a starter from a 220 Volt fluorescent lamp. It is recommended to check the LED connections first. If the extreme elements of the groups are connected by anodes to each other, then you will need to redo the circuit and connect the LEDs with cathodes. The point is that the voltage to the anode to normalize the operation of the starter must be supplied through a 5-watt resistor, while the resistance is 15-20 kOhm. In addition, additional diodes will need to be included in the circuit, which will pass the reverse current of the network through them. This is how Chinese LED garlands are repaired at home.

As you can see, you will have to spend a lot of time and patience to repair the garland. Therefore, if it is not so expensive, it is recommended to simply replace it with a new one of better quality. It is important to note that if it is the LED that burns out, after which the operation of the entire section is disrupted, then the working element should be soldered in, strictly observing the polarity.

If the light bulbs are broken and there is a desire to repair the device, then it is advisable to simply replace the damaged light source. It should be noted that replacement is carried out only with the power turned off to avoid electric shock. In such situations, you should pay tribute to unbreakable light bulbs, since you do not always have to deal with malfunctions.

So, if you find that the garland does not work, then you should try visually and using a tester to identify the problem area and cut it out. After which the working sections must be connected using special connectors. At this point the repair can be considered complete.

As a rule, breaking a garland before the New Year is not always pleasant, but it is quite possible to repair the old one or purchase a new one. It is important to remember that repairs require special knowledge, such as working with the circuit board and replacing light bulbs. Therefore, in order not to waste your nerves and time, it is recommended to buy a new New Year’s garland.

This article offers an excellent selection of diagrams for New Year's garlands and other electronic toys for the New Year's interior, based on the principles of autonomous and economical power supply, as well as the simplicity and reliability of assembling amateur radio structures.

LEDs of various types are used as the main radio component emitting light in all garland circuits. First of all, this allows you to significantly reduce the consumption of the battery source, as well as achieve unique and unpredictable New Year's pictures on a magical night.

Children are very fond of interesting and unusual things, especially flashing lights, so to the delight of the little ones, I suggest assembling a fairly simple version of the mini garland scheme. A printed circuit board in the popular amateur radio format Sprint Layout is attached in the archive above.

The circuit consists of a clock pulse generator on a domestic digital chip DD1 type K155LA3, the “power” part is made of bipolar transistors VT1-VT4, you can use almost any n-p-n structures, even KT315, if you still have them of course. An LED load and “switches” on logic elements DD2-DD4 with RC circuits R5C2, R7C3 between them are connected to the Transistors to set the turn-on delay time of the three output semiconductors.

In general, “children's joy” works as follows: Pulses follow from the generator to DD1.2, then opens VT2, then C2 is charged and as soon as the voltage on it reaches the level of logical unit “1”, then the output of element DD1.3 will also be unit that opens VT3. With DD1.4 the work is similar. The switching frequency is adjusted by selecting C1. As a result, a feeling of running lights appears.

I bring to the attention of readers diagram of a simple New Year's flasher, which can be originally made in the shape of a cross as a souvenir for the Easter or Christmas holidays. The shape of the flasher can be easily changed and used as an element of illuminated advertising.

The schematic diagram is shown in the figure. The LEDs are arranged in the shape of a cross, the circuit is made using the K561LA7 microcircuit. A rectangular pulse generator with a frequency of about 1 Hz is assembled on elements DD1.1, DD1.2, C1, R1, the transistor switch VT1 provides the necessary current for the HL1 LEDs. . . HL10, capacitor C2 is necessary if you need a smooth increase and decrease in the brightness of the LEDs - this is more pleasing to the eye. The resistance of resistors R3... R6 is selected (270-620 Ohms) so that the LED glow level is the same. Switch SA1 can be used to turn the display off or on in continuous lighting mode.

In this scheme, the number of LEDs can be increased to 12, from which you can create various decorative geometric shapes. If you use imported LEDs such as AND123R, which have appeared on our radio markets, the brightness of the glow will increase significantly.

This simple scheme is thirty years old, but it works great every new year in our home. The circuit is powered by a parametric stabilizer based on a D814D zener diode. The master oscillator is made on a K176IE12 counter with a quartz resonator with a period of 1 second. The signal from the counter output goes to a decoder made on the K561IE8 microcircuit. Positive pulses from its outputs are sent through diodes to the KT315 transistor, and the thyristor opens.

For a softer and more comfortable cozy glow, it is better to use ordinary light bulbs, which with both branches fit into the bridge rectifier and light up at full intensity. At the moment when the thyristor opens, some of the lamps are bypassed and the rest begin to glow at full intensity - this must be taken into account. The transformer can be taken from an old TV.

The circuit has mains voltage isolation, and even if you accidentally touch the power wires of the lamps, no harm will happen.

I think everyone will recognize the circuit of this simple multivibrator for two channels on two transistors. There can be many LEDs in each arm. Well, why not a super simple New Year's flasher that can be assembled on a circuit board in 5 minutes.

And if you want to use three arms, you can recall from an electronics course a multivibrator circuit with three transistors.

A correctly assembled circuit starts working immediately. Supply voltage from 5 to 9 V. Flashing frequency, i.e. The pulse sequences are selected using capacitors. It is advisable to use low-power LEDs with the same parameters.

Let's look at several simple circuit implementations. The first diagram reproduces the effect of “running lights” for three garlands. The basis is a circuit of three inverters of the K555LN1 digital microcircuit. The circuit works in such a way that at any given time only one of the inverters has a signal; accordingly, only one of the three garlands lights up, and the next one lights up when the previous one goes out.

The second circuit also allows you to achieve the effect of “running” lights, but with the ability to regulate the speed of switching the garlands, using a rectangular pulse generator. The switching frequency of the garlands is changed using resistor R3.

Another version of the Christmas tree garland switch circuit is similar to the previous one, but is assembled on CMOS chips and the frequency is adjusted by resistor R2.

The circuit is used to control a Christmas tree garland. A thyristor control module is built on bipolar transistors VT1, VT2 and resistors R3-R6. The flash frequency of the garland can be adjusted within a wide range by changing the parameters of the resistances R1, R2 and capacitor C1.